In 2005, with the adoption of the product-based production and management philosophy, Tekno started to serve in the area of Antivibration and Sealing in Passenger Cars in terms of continiuous improvement and development understanding.

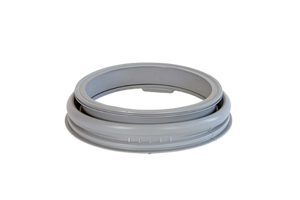

Home Appliance Industry

Tekno Kauçuk is the leader in its sector in being a supplier of rubber parts for the white-goods industry, both in Türkiye and all around the world. Since 1996, our products have been exported to companies in four different continents.

Brake Diaphragms

One of the most important component in the air brake system of commercial vehicles is textile inserted rubber diaphragms.Our diaphragms are preferred among the major OEMs throughout the world, and they provide driving safety of more than 15 million heavy vehicle's brake system.

Engineering

Tekno Kaucuk differentiates from its competitors by its codesigner capacity and capabilities in its main products. Tekno will be next to its customers not only with its products and expert engineers who have deep knowledge about the products' applications areas and conditions.

COMPANY

Who are

we?

Since 1959, Tekno is committed to be a respected and valued manufacturer of rubber parts for the industry. We have been providing our customers with superior quality products and innovative solutions, which are produced under the brand name "Doğan Lastik". After the restructuring of our company in 2001, in order to respond to our customer's expectations better, we have chosen some areas to specialize in. This way we can provide our worldwide customers the best products and services possible, with the supplying of the right products at the right time.

While doing this we seek that everyone who's involved in our system are really participating in our cycles and are satisfied with the things that they get.

News

CAREER

We know that the most valuable assets that our company possesses are our employees.

We will implement a training and incitement system that will help our employees to develop themselves continuously. These activities will be done under the philosophy of "Total Quality Management".

Plants

Plants